Drifter Merch’s blog features news, events, tour dates and vendor spotlights to music and album reviews.

Direct to Film vs Screen Printing: Which Method is Best for Your Custom Apparel?

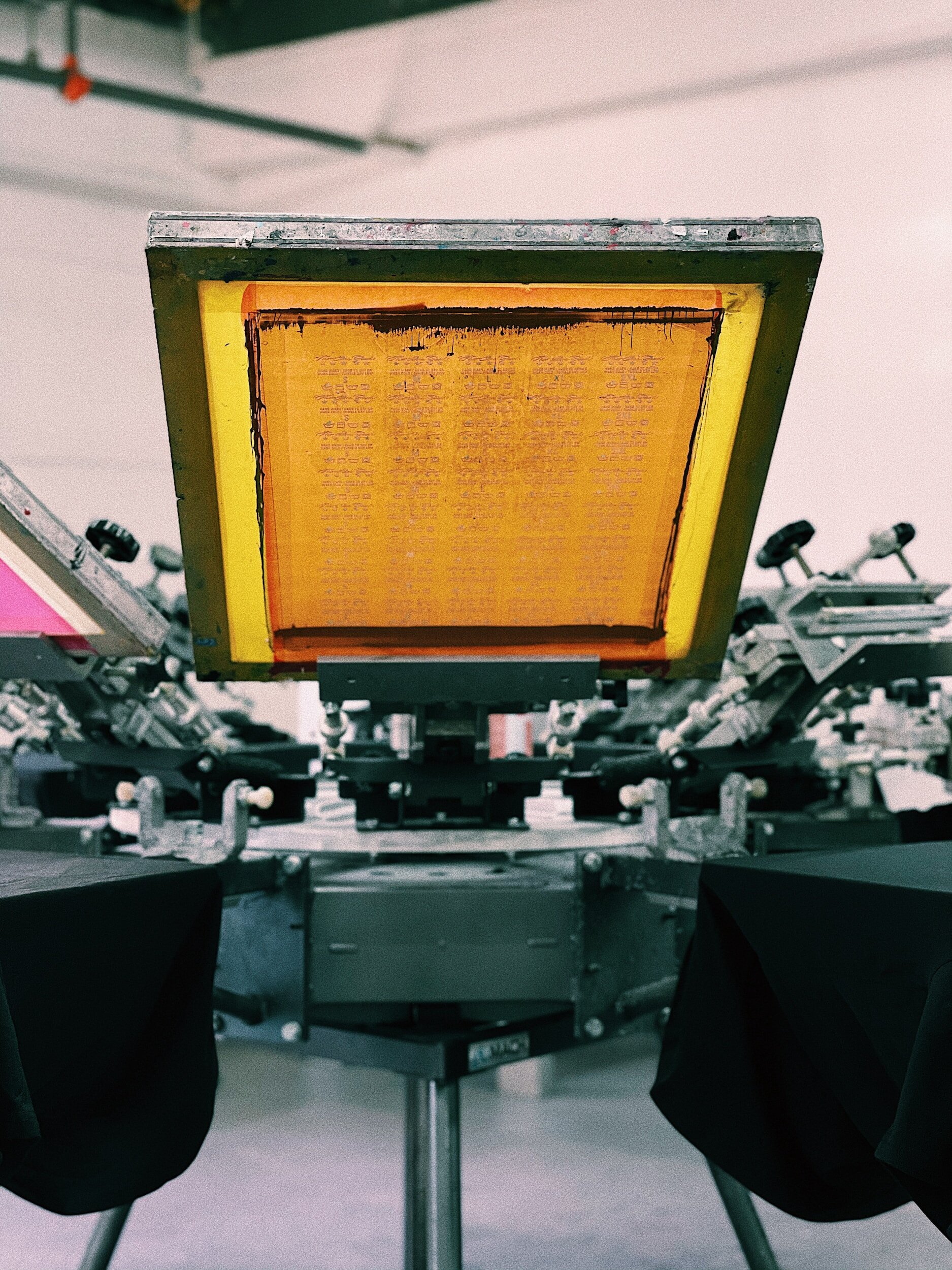

While we offer both processes for custom printing, we are often asked what the differences are between the two. Direct to Film (DTF) Printing and Screen Printing are both popular methods for printing designs on apparel and other materials, but they have distinct differences in terms of process, cost, quality, and ideal use cases. Here's a breakdown of the two methods:

1. Process

Direct to Film (DTF) Printing:

DTF involves printing a design directly onto a special film (transfer paper) using a specialized inkjet printer.

After printing, the design is coated with a powder adhesive and heat-pressed onto the fabric.

This method is relatively quick, as it doesn’t require screens or plates like traditional screen printing.

Screen Printing:

Screen printing involves creating a stencil (or "screen") for each color in the design. Ink is then pushed through the mesh screen using a squeegee, transferring the design onto the material.

Each color requires a separate screen and pass, making it a more labor-intensive process, especially for multi-color designs.

2. Cost

DTF Printing:

Lower setup costs: There’s no need for screens, which reduces initial setup costs.

Higher per-print costs: While the setup is cheaper, the cost per print can be higher, especially for smaller quantities. Ink and transfer film can add to the cost.

Screen Printing:

Higher setup costs: Creating the screens and setting up the press is labor-intensive, so there is a higher initial cost, especially for multi-color designs.

Lower per-print costs: Once the setup is done, the cost per print is lower, making it more cost-effective for large orders.

3. Print Quality

DTF Printing:

High detail and color accuracy: DTF can reproduce very detailed designs and has high color vibrancy, especially for full-color or photographic images.

Soft feel: The print can feel softer compared to screen printing, as the ink is transferred onto the fabric with a heat press, without being raised.

Screen Printing:

Durability and texture: The ink in screen printing sits on top of the fabric, which can give it a thicker, more durable feel. It’s often preferred for designs where texture (such as puff or specialty inks) is desired.

Less detail in fine prints: For very detailed designs, screen printing may not be as sharp as DTF, especially if there are fine lines or gradients.

4. Ideal Use Cases

DTF Printing:

Best for full-color, intricate, or photographic designs, particularly for smaller quantities or custom jobs.

No color limit: Unlike screen printing, which requires a separate screen for each color, DTF can print full-color designs in one pass.

Ideal for personalized items or custom orders with complex graphics.

Screen Printing:

Best for large quantities with fewer colors (usually 1-4 colors), as the cost per print decreases with larger orders.

High durability: Excellent for long-lasting designs, especially on cotton-based fabrics.

Often used for simple logos, t-shirts, and bulk orders.

5. Speed and Turnaround

DTF Printing:

Faster setup time: DTF can be faster for small orders because there’s no need to create screens.

Great for on-demand printing: Ideal for custom and smaller runs, offering a quick turnaround.

Screen Printing:

Slower setup time: Requires more time to set up each color and screen, making it slower for smaller runs.

Faster for large orders: Once set up, screen printing is faster for bulk production.

6. Versatility

DTF Printing:

Works on a variety of fabrics: DTF can be used on a wide range of materials, including cotton, polyester, and blends, as well as non-fabric items like mugs and phone cases.

Screen Printing:

Limited by fabric type: While it can work on many materials, it’s most commonly used on fabrics like cotton, polyester, and some blends.

Special inks (like the plastisol we use) and techniques can be used to print on other surfaces.

Summary:

DTF Printing is ideal for small runs, complex designs, and full-color prints.

Screen Printing is best for large runs, simpler designs, and offers durability, making it perfect for bulk production of classic designs or logos.

Choosing between the two methods depends on your specific needs regarding design complexity, volume, fabric choice, and budget. If you have any questions, be sure and ask us. We’d be happy to answer your questions and get your printing process started!

20 Common Misconceptions in the Screen Printing Industry

As a consumer, it’s easy to assume that all screen printing processes are the same, but there are many misconceptions that can affect the quality and outcome of your custom products. Understanding the truth behind these myths can help you make informed choices for your next screen printing order.

All ink types are the same – Different inks, such as plastisol and water-based, have distinct properties and applications.

Screen printing is outdated – Despite advances in digital printing, screen printing remains popular for vibrant, durable designs.

Any design can be printed – Intricate designs with fine details or gradients can be difficult to reproduce accurately.

Screen printing is always cheap – Quality materials and complex designs can increase costs.

You can print on any fabric – Some fabrics, like nylon or polyester, require special inks or processes.

All prints look the same – Ink type, technique, and fabric affect the look and feel of the final print.

You can print unlimited colors – More colors mean more screens, increasing the complexity and cost.

Screen printing is easy – It requires expertise, precision, and attention to detail for high-quality results.

Screens last forever – Screens wear out over time and need to be replaced after repeated use.

Heat press and screen printing are the same – They are different methods with distinct outcomes and uses.

Screen printing doesn’t last long – Properly applied prints can be very durable with the right care.

Any printer can handle bulk orders – Not all shops have the equipment or capacity for large-volume jobs.

No setup time is needed – Setting up screens and aligning designs can be time-consuming, especially for multi-color prints.

Screen printing is always eco-friendly – While some eco-friendly options exist, traditional methods may involve harmful chemicals.

All printers offer the same quality – Quality varies depending on the printer’s experience, equipment, and materials used.

You can change a design mid-run – Once the screens are set, altering the design is difficult and costly.

Light inks work well on dark shirts – Often, light-colored ink on dark fabric requires a base layer for opacity.

Digital printing will replace screen printing – Both methods have their advantages, with screen printing excelling in large runs.

More ink means better quality – Too much ink can create stiff, uncomfortable prints, especially on garments.

Expensive equipment guarantees better results – High-quality prints depend on the skill of the printer, not just the equipment.

By knowing the facts, you can ensure you get the best quality, durability, and value from your screen printing projects. Don’t let common misconceptions steer you wrong. Make informed decisions and enjoy top-notch results!

Understanding Minimums in Screen Printing: What You Need to Know

Screen printing is a popular and versatile method of printing used for a wide range of applications, from custom t-shirts to promotional products. If you're considering screen printing for your project, you may have come across the term "minimums." In this blog post, we'll delve into the concept of minimums in screen printing and explain what you need to know to navigate this aspect of the printing process.

Understanding Minimums:

In the context of screen printing, minimums refer to the minimum quantity of items that a printer requires for a specific design or order. Printers often impose minimums to ensure that the production process is efficient and cost-effective. These minimums can vary depending on factors such as the complexity of the design, the type of item being printed, and the capabilities of the printing facility.

There are several reasons why screen printing minimums exist:

1. Set-Up Costs: The screen printing process involves creating custom screens for each color in the design, preparing the printing equipment, and aligning the screens accurately. These set-up tasks require time, effort, and materials. By setting minimums, printers can distribute these costs over a larger quantity of items, making the process economically viable.

2. Efficiency: Screen printing is a sequential process, where each color in the design is applied separately. To optimize production time and resources, it is often more efficient to print multiple items at once. Minimums help printers maintain a workflow that maximizes efficiency and reduces downtime.

3. Profitability: Printing businesses need to cover their costs and make a profit to stay sustainable. By setting minimums, printers can ensure that each order meets a certain threshold of profitability necessary to run their operations successfully.

Here are a few tips to help you navigate minimums in screen printing:

1. Communication: When considering screen printing for your project, it's essential to research potential printing companies and their minimum requirements. Reach out to the printers directly and discuss your specific needs. Clear communication will help you understand the minimums they have in place and explore any potential flexibility based on your requirements.

2. Cost Considerations: Minimums are often tied to the cost per item. As the quantity increases, the per-item cost tends to decrease. Evaluate your budget and determine the optimal quantity that strikes a balance between affordability and meeting the printer's minimums.

3. Group Orders: If you don't require a large number of items yourself, consider joining forces with friends, colleagues, or community groups who may have similar printing needs. By combining orders, you can collectively reach the printer's minimums and share the cost, making it more feasible for everyone involved.

Minimums in screen printing serve a practical purpose, helping printers streamline their production process and maintain profitability. By understanding the reasons behind minimums and effectively communicating with printing companies, you can navigate this aspect of screen printing and find the right balance between quantity, cost, and quality for your specific project. If you are interested in screen printing, please reach out as we offer custom orders.

Learn Differences Between Printing Processes

When ordering t-shirts, it's important to understand the different printing methods. Our website and Etsy offer screen-printed designs using plastisol ink, while Amazon purchases come with DTG printing. Our custom flags and tents are created through sublimated printing. What does this mean? Screen printing, heat press, vinyl, DTG (Direct-to-Garment), and sublimation are all different printing methods, each with its own advantages and considerations.

1. Durability: Screen printing often provides excellent durability and long-lasting prints. The ink used in screen printing is typically thicker and more robust, making it more resistant to fading, cracking, or peeling over time, especially when compared to heat press and vinyl transfers.

2. Vibrant Colors and Opaqueness: Screen printing allows for the use of vibrant and opaque colors. The ability to apply multiple layers of ink during the printing process produces vibrant and eye-catching designs, even on dark-colored garments. In comparison, heat press and vinyl transfers may have limitations in color vibrancy and opacity.

3. Cost-Effective for Large Orders: Screen printing becomes cost-effective when producing large quantities of printed items. Once the screens are set up, printing multiple items becomes relatively efficient, making it a preferred choice for businesses that require a high volume of printed products. Heat press, vinyl, DTG, and sublimation printing may have higher costs per unit for larger orders.

4. Versatility: Screen printing can be performed on various surfaces, including fabrics, paper, plastics, and wood, making it suitable for a wide range of applications. Heat press and vinyl transfers are primarily used on fabrics, while DTG and sublimation printing are more specialized for fabric applications.

5. Customization Options: Screen printing offers a wide range of customization options, including the use of special inks (e.g., metallic or glow-in-the-dark inks), specialty finishes (e.g., foil or flock), and textured effects. This flexibility allows for unique and creative designs. While heat press and vinyl transfers offer some customization options, they may have limitations in terms of effects and finishes. DTG and sublimation printing also offer customization options, but they may have limitations in terms of special effects and the type of fabrics they can be used on.

It's important to note that each printing method has its own strengths and weaknesses, and the better option depends on specific requirements, such as desired print quality, quantity, fabric/material, complexity of the design, budget, and available equipment. It's always recommended to consider these factors and discuss with us or your printing professional to determine the most suitable method for your specific needs.